fabrication of welded steel structures, as well as cold-rolled galvanized. Every CFS component has at least 25% of recycled steel that adds another advantage to green buildings. Construction company The Center of frame construction is a company of the. These buildings are also built with high standards, making them seismic proof and capable of withstanding high winds. Thus, the quality of the steel will remain consistent for decades without getting damaged from moisture, timber, rust, or fire. To meet your steel building requirements, steel framing is available in varying thicknesses. On contrary to hot-rolled steel, cold-formed steel is made in common forms like steel plates, strips, and columns, without any welding requirements. 1: Dimensions for hot rolled steel beam, column, channel and angle sections. Hot rolled steel is manufactured at high temperature that results in steel welding joints. If you are using Tekla Structural Designer or Tekla Portal Frame Designer. CFSF products include cold-formed studs, joists, rafters, trusses and miscellaneous bracing and connection components. This publication is intended as a guide for designers of cold-formed steel framing (CFSF) systems for buildings. The Cold-Formed Steel Buildings can confront fire, storm, flood, and other weather issues.Ĭold-formed steel (CFS) is more preferred over hot-rolled steel. AISI Cold-Formed Steel Framing Design Guide, Second Edition Page i. It gives a powerful boost to your BIM workflow.

Metal Framing Roof lets Revit® users instantly create metal truss and/or rafter systems of any shape or complexity, perform structural analysis, and generate custom shop drawings. A complete steel structure is erected using the ‘C’ shape steel bars, which are settled on the bay using various other construction components, including knee braces, apex braces, cross bracing, and more. Design prefabricated metal frame roof panels, cold formed steel roof trusses and rafter systems. Tekla also links to project management applications that further help the users understand and visualize the true scope and context of schedule line items, material ordering, payment requests, and the objects that other project parties create.Cold-formed steel doesn’t have any welding instead, entire components are made using cold procedures like squeezing, trimming, twisting, etc. The benefits of this open approach include better layout coordination and structural information that supports leaner construction.

Tekla structures cold formed steel framing software#

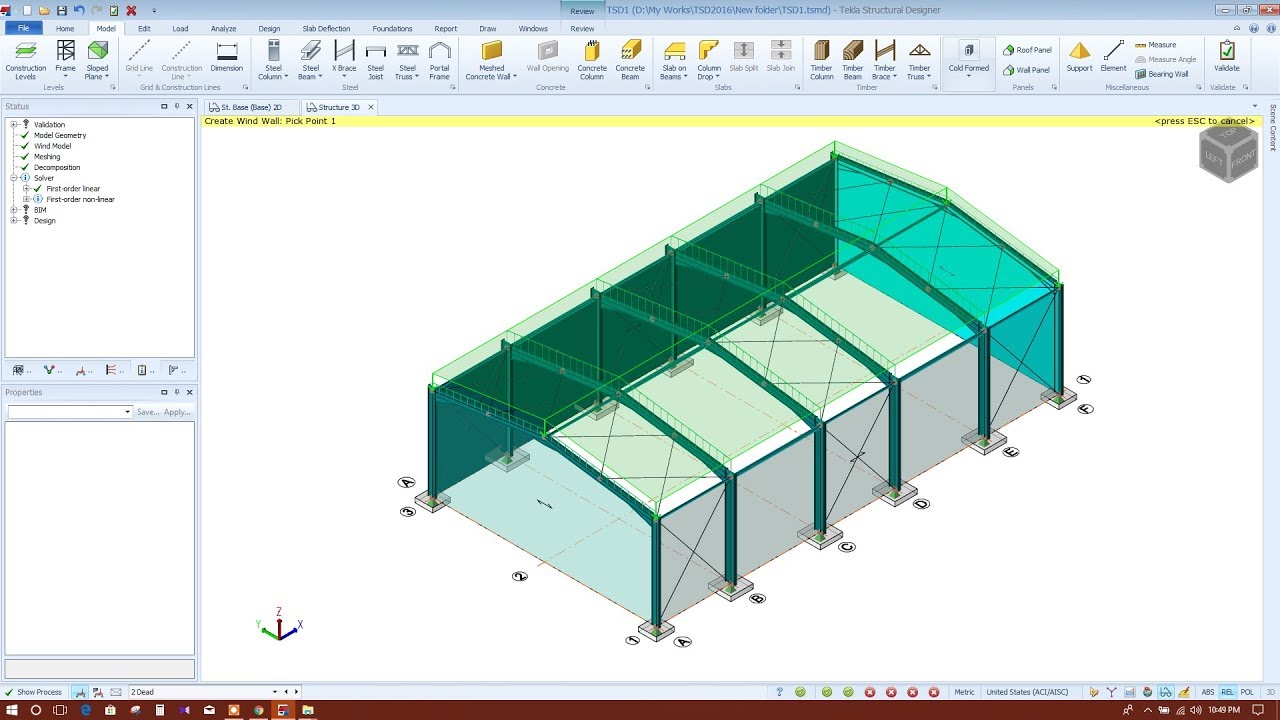

Used to model stadiums, residential buildings, skyscrapers, bridges, offshore structures, plants and factories Tekla Structures has been used on projects large or small and is able to deal with the most complex projects. Tekla Structures improves the way of working within your business and externally by creating accurate ways of working and streamlining collaboration between all parties at all stages of the construction project.

Tekla Structures is intelligent 3D modelling software that produces 3D models containing accurate, reliable and detailed information suitable for manufacture and construction execution.

0 kommentar(er)

0 kommentar(er)